Delaware Dyamics is the leader of world-class design and tooling manufacture. Our ongoing investments in the future now provide customers a DieCasting Technology Center with capabilities that are second to none. Delaware Dynamics is the only die cast tooling supplier in the world with three differently sized on-site die casting machines for providing customers with a turnkey die casting solution. Our facility is representative of the size and type of die cast machines being used throughout the industry today. We are committed to providing our customer with the ability to duplicate and improve their processes before the tool is delivered.

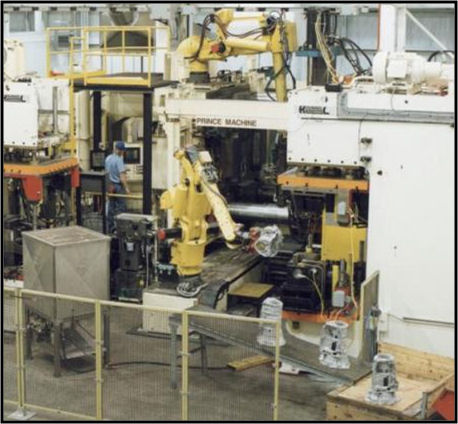

The 3500 Ton Prince Machine is a re-configurable flexible manufacturing cell, including three individual robots for spray, insert/cylinder liner loading, metal delivery, and part extract. This fully automated cell also has access to two trim presses, quench cooling, hot oil, 2-stage vacuum, dosing, furnace multiple shot ends, and basic part verification with the latest process control maintaining coordination.

The 2000 Ton and 1600 Ton Prince Machines are configured in a manufacturing cell with robotic spray and robotic part extract. Each of these die casting cells also have the capability for integrating robotic trim and casting cooling.

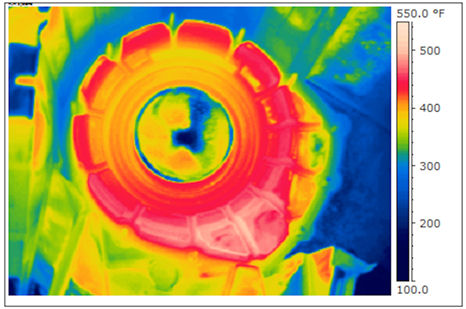

Complementing the die cast process is our ability to evaluate the castings by both destructive and non-destructive means. We can offer additional services from our multi-pallet high speed machining centers to machine castings from a cube state thru finish machined parts. Casting dimensional integrity for PPAP validation is performed our multiple Coordinate Measuring Machines. Internal casting structure is achieved in real time via the resident CT Scan equipment. This full service assures our customers a quality product entering their plant from the onset.

Production of early prototype parts for reliability testing and transfer line verification plus rapid prototyping and limited production runs are commonplace to our facility. Part sizes from small multi-cavity components to large V-Engine blocks, with up to three different alloy simultaneously, sets us apart from any tool builder in the world.