Pioneered by Delaware Dynamics, die program component interchangeability and cavity dimensional accuracy has been a turnkey standard in our tooling for over 2 decades. This has allowed our customers to have greater flexibility in multiple die programs and confidence in off-the-shelf replacement tooling that is ready for production. Specializing in large, complex multi slide large cavity parts designs, our engineering services group has launched notable pilot V-Block and transmission programs for GM, Ford and Chrysler LLC.

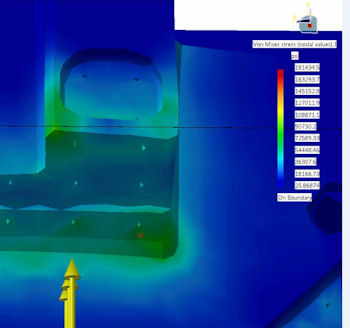

A full range of CAD/CAE/CAM/CMM software, including Catia V5, and Siemens NX9, allows direct support of customer data. A compliment of supporting software adds stress analysis using FEA capabilities with Unigraphics and Catia, numeric manufacture and inspection, rapid prototyping, casting process evaluation, and facility layout planning.

Engineering Analysis

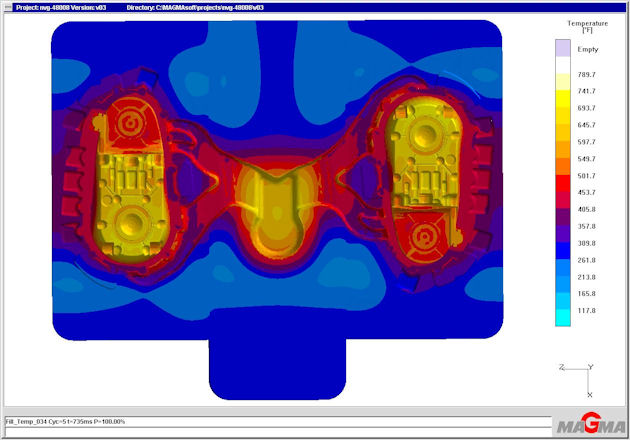

Magmasoft’s latest High Pressure Die Cast module, running on a dedicated 16 Core 64bit processing workstation, is an integral part of our full service engineering support. This simulation software is used to predict metal flow, tooling and part thermal conditions, gas entrapment and venting-vacuum possibilities, giving the customer an advanced picture of the die cast process before the tool is production.

Experience in tool design and process analysis beyond the basics is a standard within engineering at Delaware Dynamics. Experienced in 3D modeling for over two decades, our group routinely performs part deviation for process/product updates for the customer.

Engineering CAM/CMM

Our tooling is manufactured and inspected from high speed machining centers and coordinate measuring equipment that is interfaced directly to our engineering network. We use the latest manufacturing software to produce numerical programs that cut and validate all the steel that advances through our facility. All of our programming is constructed and verified to the tool design database, allowing for extremely accurate component fit and interchangeability within the customer’s family of tools.